Home > Press > Atomic level deposition to extend Moores law and beyond

|

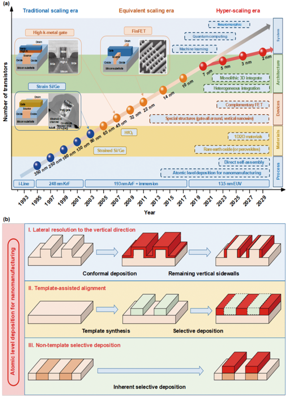

| The downscaling of nanomaterials, nanostructures, nanodevices and nanosystems needs atomic level deposition, and there are three characteristics of atomic level deposition including bringing lateral angstrom resolution to the vertical direction, template-assisted alignments with high accuracy, non-template selective deposition.

Credit: by Rong Chen, Yi-Cheng Li, Jia-Ming Cai, Kun Cao, Han-Bo-Ram Lee |

Abstract:

Moores law has driven the semiconductor industry to continue downscaling the critical size of transistors to improve device density. At the beginning of this century, traditional scaling started to encounter bottlenecks. The industry has successively developed strained Si/Ge, high-K/metal gate, and Fin-FETs, enabling Moore’s Law to continue. Now, the critical size of FETs is down to 7 nm, namely theres almost 7 billion transistors per square centimeter on one chip, which brings huge challenges for fin-type structure and nanomanufacturing methods. Up to now, extreme ultraviolet lithography has been used in some critical steps, and it is facing alignment precision and high costs for high-volume manufacturing. Meanwhile, the introduction of new materials and 3D complex structures brings serious challenges for top-down methods. Newly developed bottom-up manufacturing serves as a good complementary method and provides technical driving force for nanomanufacturing. As early as 1959, Prof. Feynman speculated, Theres plenty of room at the bottom. This talk inspired human beings to manipulate atoms or molecules as building blocks for designed structures. Atomic level deposition is a typical representative for bottom-up strategies. In the first section, the deposition brings lateral angstrom resolution to the vertical direction as well as top-down etching, such as double patterning. Next, various template-assisted selective deposition methods including dielectric templates, inhibitors and correction steps have been utilized for the alignment of 3D complex structures. Finally, atomic scale resolution can be achieved by inherently selective deposition. Low dimensional materials and emerging applications are discussed, including 2D materials, nanowires, nanoparticles, etc. In this article, Professor Rong Chen gave a detailed introduction to the recent progresses of atomic level deposition and its potential to extend Moores law and beyond.

Atomic level deposition to extend Moores law and beyond

Wuhan, China | Posted on July 15th, 2022

The atomic level deposition methods are characterized by the conformality and uniformity of thin films. Atomic level deposition can bring lateral resolution to the vertical direction for diversified structures with high aspect-ratios, including sidewalls, nanowires, nanotubes and so on. Self-aligned double patterning is a typical example for vertical resolution. Atomic level deposition can improve the accuracy of nanopatterning and obtain some special structures, which can further reduce the feature size and increase the density of transistors, thereby promoting the continuation of Moore’s law in the short term.

With the devices become more complex, the aligned growth of thin films has been considered as an essential aspect during nanomanufacturing. Selective deposition is an efficient and promising method to achieve alignment, which can reduce steps such as photolithography and etching. Normally, its effective to achieve deposition with high selectivity by using special templates. With the help of the templates, chip makers could not only superimpose transistors directly in three dimensions, but also integrate multi-functionality, such as sensing, energy storage, into chips to manufacture super-chips.

It is quite challenging to prepare appropriate templates for selective deposition of low dimensional materials and complex 3D structures by current top-down approaches, non-template selective deposition has been studied. For the post-Si era, atomic level deposition can prepare many alternative nanomaterials, such as 2D materials, carbon materials, ferroelectric materials, phase transition materials and so on, which can overcome the constraints of the physical limits of silicon materials and broaden the boundaries of Moore’s law.

Professor Chen Rong and other researchers in her group have identified a few critical challenges in the field of atomic level deposition:

Atomic level deposition is a versatile future-oriented deposition technology, which is bound to play an increasingly important role in the field of micro-nano manufacturing. The chip makers have shown strong interest in this technology. In addition to the field of microelectronics, atomic scale deposition has a wide range of applications in optoelectronics, energy storage, catalysis, biomedicines.

To achieve nanomanufacturing with high precision, the mechanism of atomic level deposition needs in-depth study.

Although the characterization technologies are booming, the single-atom characterization and manipulation technology still have vast room for improvement.

To achieve complex nanostructures fabrication, multiple processes coupling is indispensable for various materials. But how to achieve process integration?

Besides fabricating thin films and nanostructures with high precision, accuracy and processing efficiency are inter-inhibitive factors. How to achieve reliable high-volume manufacturing in industry?

Researchers have suggested that atomic level deposition could be used to extend Moores law and beyond. Atomic level deposition is becoming an increasingly promising technology for the precise fabrication of complex nanostructures, enables the creation of equivalent topography with a better control over the film thickness and without roughening the surface. It is considered as an enabling technology in advanced semiconductor technology nodes and other emerging fields.

####

For more information, please click here

Contacts:

Media Contact

Yue YAO

International Journal of Extreme Manufacturing

Expert Contact

Rong Chen

Huazhong University of Science and Technology

Copyright © International Journal of Extreme Manufacturing

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

News and information

![]()

Study reveals new mode of triggering immune responses July 15th, 2022

![]()

A novel graphene based NiSe2 nanocrystalline array for efficient hydrogen evolution reaction July 15th, 2022

Possible Futures

![]()

Recent advances in 3D electronics July 15th, 2022

![]()

Life-like lasers can self-organise, adapt their structure, and cooperate July 15th, 2022

Chip Technology

![]()

Recent advances in 3D electronics July 15th, 2022

![]()

Life-like lasers can self-organise, adapt their structure, and cooperate July 15th, 2022

Nanoelectronics

![]()

Controlled synthesis of crystal flakes paves path for advanced future electronics June 17th, 2022

![]()

Eyebrow-raising: Researchers reveal why nanowires stick to each other February 11th, 2022

![]()

Visualizing temperature transport: An unexpected technique for nanoscale characterization November 19th, 2021

Discoveries

![]()

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]()

Life-like lasers can self-organise, adapt their structure, and cooperate July 15th, 2022

Announcements

![]()

Recent advances in 3D electronics July 15th, 2022

![]()

Life-like lasers can self-organise, adapt their structure, and cooperate July 15th, 2022

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]()

Recent advances in 3D electronics July 15th, 2022

![]()

Life-like lasers can self-organise, adapt their structure, and cooperate July 15th, 2022

Tools

![]()

New technology helps reveal inner workings of human genome June 24th, 2022

![]()

Snapshot measurement of single nanostructures circular dichroism March 25th, 2022

![]()

Eyebrow-raising: Researchers reveal why nanowires stick to each other February 11th, 2022