Home > Press > Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell

|

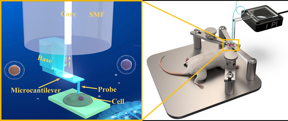

| Fiber optical nanomechanical probe (FONP) fabricated by femtosecond laser two‐photon polymerization technology can realize the biomechanical measurement down to 2.1 nanonewton. Such high precision enables the measurement of in vivo biomechanical properties of tissue, single cell, and other soft biomaterials.

CREDIT By Mengqiang Zou, Changrui Liao, Yanping Chen, Lei Xu, Shuo Tang, Gaixia Xu, Ke Ma, Jiangtao Zhou, Zhihao Cai, Bozhe Li, Cong Zhao, Zhourui Xu, Yuanyuan Shen, Shen Liu, Ying Wang, Zongsong Gan, Hao Wang, Xuming Zhang, Sandor Kasas and Yiping Wang. |

Abstract:

Fiber sensing scientists at Shenzhen University have developed a compact fiber optical nanomechanical probe (FONP) for measuring in vivo biomechanical properties of tissue and even single cell.

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell

Shenzhen, China | Posted on February 10th, 2023

Publishing in the journal International Journal of Extreme Manufacturing, the researchers from Shenzhen University applied femtosecond laser-induced two‐photon polymerization technology to fabricate fiber-tip microprobe with ultrahigh mechanical precision down to 2.1 nanonewton.

This high-precision mechanical sensing system enables the measurement of in vivo biomechanical properties of tissue, single cell, and other types of soft biomaterials. The findings could have a widespread impact on the future development of all-fiber Atomic Force Microscopy for biomechanical testing and nanomanipulation.

One of the lead researchers, Professor Yiping Wang, commented, “The biomechanical properties of different tissues in the human body range widely with seven orders of magnitude, from the softest cells to the stiffest bones. We have developed a flexible strategy that could design and fabricate the fiber-tip microprobes with the most fitted spring constant for the accurate in vivo biomechanical measurement of almost all the tissues in the human body.

Atomic Force Microscopy (AFM) is one of the few technologies that could perform delicate biomechanical measurements. However, there are typical limitations of bench-top AFM system in its size and complex feedback system. It also requires certain geometry of the samples to be measured, which further limits its application in biomechanical measurement in vivo. First author Dr. Mengqiang Zou claimed, “Our work achieved a new generation of all-fiber AFM with the flexible methodology to achieve the best design of the fiber-tip microprobe for every in vivo test, which was turned out to be reliable and also much more miniaturized.

Professor Changrui Liao has pioneered the fiber-tip microdevices fabricated by femtosecond laser-induced two-photon polymerization technology for gas sensing. Here his group has developed the technology to achieve various fiber-tip microstructures, specifically in terms of microcantilevers with additional topological design, to achieve microprobes with a series of spring constants. This development allows the all-fiber AFM to become a next-generation tool for basic research involving the in vivo biomechanical measurement of various types of tissues.

The team utilized the finite element method and topological theory to optimize the design of fiber-tip microcantilever probes. The finest microprobe could reach a reliable measuring capability down to 2.1 nanonewton. Professor Sandor Kasas said, “This is a milestone achievement and it is only the beginning. We anticipate this technique to become a powerful tool for in vivo biomechanical study of human tissue and cells, to further understand the fundamentals of biomechanical changes related with diseases such as cancer, and also in the critical processes of developmental biology.

####

About International Journal of Extreme Manufacturing

International Journal of Extreme Manufacturing (IF: 10.036) is a new multidisciplinary, double-anonymous peer-reviewed and diamond open-access without article processing charge journal uniquely covering the areas related to extreme manufacturing. The journal is devoted to publishing original articles and reviews of the highest quality and impact in the areas related to extreme manufacturing, ranging from fundamentals to process, measurement and systems, as well as materials, structures and devices with extreme functionalities.

For more information, please click here

Contacts:

Yue YAO

International Journal of Extreme Manufacturing

Expert Contact

Changrui Liao

Shenzhen University

Copyright © International Journal of Extreme Manufacturing

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

News and information

![]()

Graphene Flagship start-up Bedimensional closes a second 10 million investment round February 10th, 2023

![]()

Make them thin enough, and antiferroelectric materials become ferroelectric February 10th, 2023

3D & 4D printing/Additive-manufacturing

![]()

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]()

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

![]()

UBCO researchers change the game when it comes to activity tracking: Flexible, highly sensitive motion device created by extrusion printing June 17th, 2022

Possible Futures

![]()

Make them thin enough, and antiferroelectric materials become ferroelectric February 10th, 2023

Nanomedicine

![]()

Team undertakes study of two-dimensional transition metal chalcogenides Important biomedical application, including biosensing December 9th, 2022

Discoveries

![]()

Make them thin enough, and antiferroelectric materials become ferroelectric February 10th, 2023

Announcements

![]()

Graphene Flagship start-up Bedimensional closes a second 10 million investment round February 10th, 2023

![]()

Photonic Materials: Recent Advances and Emerging Applications February 10th, 2023

![]()

Make them thin enough, and antiferroelectric materials become ferroelectric February 10th, 2023

![]()

Scientists reveal the effect of Cu(I) structure on quantum sieving for hydrogen isotope separation February 10th, 2023

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]()

Make them thin enough, and antiferroelectric materials become ferroelectric February 10th, 2023

Nanobiotechnology

![]()

Team undertakes study of two-dimensional transition metal chalcogenides Important biomedical application, including biosensing December 9th, 2022