Home > Press > Liquid metal sticks to surfaces without a binding agent

|

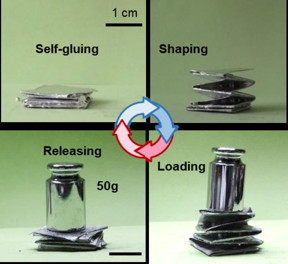

| A multifunctional Origami structure built by the liquid metal-treated paper

CREDIT Cell Reports Physical Science/Yuan et al. |

Abstract:

Everyday materials such as paper and plastic could be transformed into electronic smart devices by using a simple new method to apply liquid metal to surfaces, according to scientists in Beijing, China. The study, published June 9 in the journal Cell Reports Physical Science, demonstrates a technique for applying a liquid metal coating to surfaces that do not easily bond with liquid metal. The approach is designed to work at a large scale and may have applications in wearable testing platforms, flexible devices, and soft robotics

Liquid metal sticks to surfaces without a binding agent

Cambridge, MA | Posted on June 9th, 2023

Before, we thought that it was impossible for liquid metal to adhere to non-wetting surfaces so easily, but here it can adhere to various surfaces only by adjusting the pressure, which is very interesting, said Bo Yuan, a scientist at Tsinghua University and the first author of the study.

Scientists seeking to combine liquid metal with traditional materials have been impeded by liquid metals extremely high surface tension, which prevents it from binding with most materials, including paper. To overcome this issue, previous research has mainly focused on a technique called transfer printing, which involves using a third material to bind the liquid metal to the surface. But this strategy comes with drawbacksadding more materials can complicate the process and may weaken the end products electrical, thermal, or mechanical performance.

To explore an alternative approach that would allow them to directly print liquid metal on substrates without sacrificing the metals properties, Yuan and colleagues applied two different liquid metals (eGaln and BilnSn) to various silicone and silicone polymer stamps, then applied different forces as they rubbed the stamps onto paper surfaces.

At first, it was hard to realize stable adhesion of the liquid metal coating on the substrate, said Yuan. However, after a lot of trial and error, we finally had the right parameters to achieve stable, repeatable adhesion.

The researchers found that rubbing the liquid metal-covered stamp against the paper with a small amount of force enabled the metal droplets to bind effectively to the surface, while applying larger amounts of force prevented the droplets from staying in place.

Next, the team folded the metal-coated paper into a paper crane, demonstrating that the surface can still be folded as usual after the process is completed. And after doing so, the modified paper still maintains its usual properties.

While the technique appears promising, Yuan noted that the researchers are still figuring out how to guarantee that the liquid metal coating stays in place after it has been applied. For now, a packaging material can be added to the papers surface, but the team hopes to figure out a solution that wont require it.

Just like wet ink on paper can be wiped off by hand, the liquid metal coating without packaging here also can be wiped off by the object it touches as it is applied, said Yuan. The properties of the coating itself will not be greatly affected, but objects in contact may be soiled.

In the future, the team also plans to build on the method so that it can be used to apply liquid metal to a greater variety of surfaces, including metal and ceramic.

We also plan to construct smart devices using materials treated by this method, said Yuan.

###

This work was supported by China Postdoctoral Science Foundation, the National Nature Science Foundation of China, and the cooperation funding between Nanshan and Tsinghua SIGS in science and technology.

Cell Reports Physical Science, Yuan et al. Direct fabrication of liquid-metal multifunctional paper based on force-responsive adhesion https://www.cell.com/cell-reports-physical-science/fulltext/S2666-3864(23)00193-5

Cell Reports Physical Science published by Cell Press, is a new broad-scope, open access journal that publishes cutting-edge research across the spectrum of the physical sciences, including chemistry, physics, materials science, energy science, engineering, and related interdisciplinary work. Visit https://www.cell.com/cell-reports-physical-science/home. To receive Cell Press media alerts, please contact

####

For more information, please click here

Contacts:

Kristopher Benke

Cell Press

Copyright © Cell Press

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

News and information

![]()

Single quantum bit achieves complex systems modeling June 9th, 2023

![]()

Quantum materials: Electron spin measured for the first time June 9th, 2023

![]()

Graphene-based Carbocatalysts: Synthesis, Properties, and ApplicationsBeyond Boundaries June 9th, 2023

Wearable electronics

![]()

Breaking through the limits of stretchable semiconductors with molecular brakes that harness light June 9th, 2023

![]()

Vertical electrochemical transistor pushes wearable electronics forward: Biomedical sensing is one application of efficient, low-cost transistors January 20th, 2023

![]()

Tin selenide nanosheets enables to develop wearable tracking devices December 9th, 2022

Flexible Electronics

![]()

Breaking through the limits of stretchable semiconductors with molecular brakes that harness light June 9th, 2023

![]()

Tin selenide nanosheets enables to develop wearable tracking devices December 9th, 2022

Robotics

![]()

Robot caterpillar demonstrates new approach to locomotion for soft robotics March 24th, 2023

Possible Futures

![]()

USTC enhances fluorescence brightness of single silicon carbide spin color centers June 9th, 2023

![]()

Single quantum bit achieves complex systems modeling June 9th, 2023

![]()

Advances in nanotechnology application in biosafety materials A crucial response to COVID-19 pandemic June 9th, 2023

![]()

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Discoveries

![]()

When all details matter — Heat transport in energy materials June 9th, 2023

![]()

Advances in nanotechnology application in biosafety materials A crucial response to COVID-19 pandemic June 9th, 2023

![]()

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023

Announcements

![]()

Graphene-based Carbocatalysts: Synthesis, Properties, and ApplicationsBeyond Boundaries June 9th, 2023

![]()

When all details matter — Heat transport in energy materials June 9th, 2023

![]()

Advances in nanotechnology application in biosafety materials A crucial response to COVID-19 pandemic June 9th, 2023

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]()

USTC enhances fluorescence brightness of single silicon carbide spin color centers June 9th, 2023

![]()

Single quantum bit achieves complex systems modeling June 9th, 2023

![]()

Advances in nanotechnology application in biosafety materials A crucial response to COVID-19 pandemic June 9th, 2023

![]()

Researchers discover materials exhibiting huge magnetoresistance June 9th, 2023