Home > Press > Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact

|

| Non-uniform formation mechanism revealed

CREDIT COPYRIGHT (C) TOYOHASHI UNIVERSITY OF TECHNOLOGY. ALL RIGHTS RESERVED. |

Abstract:

Overview

Tools coated with diamond film (diamond-coated tools) are used for difficult-to-machine materials such as CFRP. In the manufacture of diamond-coated tools, a pretreatment is required to remove cobalt from the tool using a liquid in order to achieve a uniform diamond film surface. However, there are concerns about the environmental impact of liquid waste from liquid pretreatment (wet processing), and there is a need to develop a process that does not use liquids (dry processing).

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact

Toyohashi, Japan | Posted on March 24th, 2023

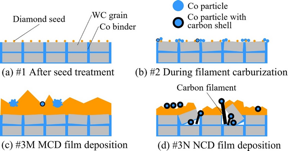

A research team consisting of masters student Yoshinori Saiki, Assistant Professor Takahiro Bando, Lecturer Toru Harigai, Professor Hirofumi Takikawa from the Department of Electrical and Electronic Information Engineering at Toyohashi University of Technology, and others has revealed the mechanism by which cobalt makes the diamond film surface non-uniform with the aim of developing a pretreatment that does not require wet processing. In particular, the team found that carbon filaments cause non-uniform formation in smooth, low-friction nanocrystalline diamond films, and that inhibition of carbon filaments is key (Fig. 1). This study was conducted in collaboration with OSG Corporation (a leading company in the Higashimikawa region) and Nagaoka University of Technology (has strong ties with our university), making it a unique research project for Toyohashi University of Technology.

Details

Tools coated with diamond film (diamond-coated tools) are used for difficult-to-machine materials. A typical example of difficult-to-machine materials is carbon fiber-reinforced plastic (CFRP), which is used as a light and hard material to reduce the weight of aircraft and automobile bodies.

As a base material of tools for depositing diamond films, cemented tungsten carbide with cobalt binder is usually used. And hot filament chemical vapor deposition (HF-CVD) is used as the film deposition technique. Figure 2 shows the film deposition process. When diamond film is deposited on cemented tungsten carbide by HF-CVD, it is known that the quality of diamond-coated tools deteriorates as the diamond film becomes non-uniform due to cobalt grains. Therefore, a pretreatment is required to remove the cobalt on the cemented tungsten carbide with liquid. However, there are concerns about the environmental impact of liquid waste from liquid treatment (wet processing), and there is a need to develop a process that does not use liquids (dry processing). In this study, we initially revealed the mechanism by which cobalt makes the diamond film surface non-uniform with the aim of developing a pretreatment that does not require wet processing.

There are two types of diamond films deposited on tools: microcrystalline diamonds and nanocrystalline diamonds. Previous research has proposed a mechanism for non-uniform formation only for microcrystalline diamonds. However, there were no findings about nanocrystalline diamonds, which are considered to be smooth, have little friction, and be more suitable for tools. In this study, we revealed the non-uniform formation mechanism for nanocrystalline diamonds as well as microcrystalline diamonds with time-resolved observation of the deposition process for microcrystalline diamonds and nanocrystalline diamonds. In particular, in nanocrystalline diamonds, the carbon filaments lift particles on the tungsten carbide substrate (Fig. 3), making the substrate non-uniform, thereby causing non-uniform formation.

Future Outlook

In this study, we showed that it is important to inhibit carbon filament growth in the initial stage of deposition in order to inhibit the non-uniform formation of nanocrystalline diamond films in dry processing. In the future, we plan to develop a deposition technique using HF-CVD in a high-temperature environment that can inhibit the growth of carbon filaments. Furthermore, after establishing a uniform formation process for nanocrystalline diamond films, we plan to apply the process to actual tools and investigate their machining performance.

####

For more information, please click here

Contacts:

Yoko Okubo

Toyohashi University of Technology (TUT)

Office: 81-532-44-6975

Copyright © Toyohashi University of Technology (TUT)

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

News and information

![]()

Optical switching at record speeds opens door for ultrafast, light-based electronics and computers: March 24th, 2023

![]()

Robot caterpillar demonstrates new approach to locomotion for soft robotics March 24th, 2023

![]()

Semiconductor lattice marries electrons and magnetic moments March 24th, 2023

![]()

Light meets deep learning: computing fast enough for next-gen AI March 24th, 2023

Thin films

![]()

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

![]()

Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

![]()

Leibniz Prize winner Professor Dr. Oliver G. Schmidt moves to Chemnitz University of Technology: President Professor Dr. Gerd Strohmeier refers to an ‘absolute top transfer’ September 10th, 2021

Possible Futures

![]()

New experiment translates quantum information between technologies in an important step for the quantum internet March 24th, 2023

![]()

Graphene grows and we can see it March 24th, 2023

![]()

HKUMed invents a novel two-dimensional (2D) ultrasound-responsive antibacterial nano-sheets to effectively address bone tissue infection March 24th, 2023

![]()

A universal HCl-assistant powder-to-powder strategy for preparing lead-free perovskites March 24th, 2023

Discoveries

![]()

New experiment translates quantum information between technologies in an important step for the quantum internet March 24th, 2023

![]()

Graphene grows and we can see it March 24th, 2023

![]()

HKUMed invents a novel two-dimensional (2D) ultrasound-responsive antibacterial nano-sheets to effectively address bone tissue infection March 24th, 2023

![]()

A universal HCl-assistant powder-to-powder strategy for preparing lead-free perovskites March 24th, 2023

Materials/Metamaterials

![]()

Graphene grows and we can see it March 24th, 2023

![]()

A universal HCl-assistant powder-to-powder strategy for preparing lead-free perovskites March 24th, 2023

![]()

Bilayer PET/PVDF substrate-reinforced solid polymer electrolyte improves solid-state lithium metal battery performance March 24th, 2023

![]()

Scientists develop self-tunable electro-mechano responsive elastomers March 3rd, 2023

Announcements

![]()

Robot caterpillar demonstrates new approach to locomotion for soft robotics March 24th, 2023

![]()

Semiconductor lattice marries electrons and magnetic moments March 24th, 2023

![]()

Light meets deep learning: computing fast enough for next-gen AI March 24th, 2023

![]()

Bilayer PET/PVDF substrate-reinforced solid polymer electrolyte improves solid-state lithium metal battery performance March 24th, 2023

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]()

HKUMed invents a novel two-dimensional (2D) ultrasound-responsive antibacterial nano-sheets to effectively address bone tissue infection March 24th, 2023

![]()

A universal HCl-assistant powder-to-powder strategy for preparing lead-free perovskites March 24th, 2023

![]()

Optical switching at record speeds opens door for ultrafast, light-based electronics and computers: March 24th, 2023

![]()

Robot caterpillar demonstrates new approach to locomotion for soft robotics March 24th, 2023

Tools

![]()

Novel microscope developed to design better high-performance batteries: Innovation gives researchers inside view of how batteries work February 10th, 2023

![]()

Shrinking hydrogels enlarge nanofabrication options: Researchers from Pittsburgh and Hong Kong print intricate, 2D and 3D patterns December 29th, 2022

![]()

Rapid fluorescent mapping of electrochemically induced local pH changes December 9th, 2022